In the photovoltaic industry, individual

solar cells cannot be used directly as a power source. Instead, they must be

connected in series and parallel and tightly packaged into modules to perform

the photoelectric conversion function. Solar photovoltaic modules are the core

component of photovoltaic power generation systems, directly converting solar

energy into direct current (DC) electricity, which is then aggregated through a

DC combiner box. The DC power is then converted into alternating current (AC)

by an inverter, ultimately enabling power consumption and access to the

internet.

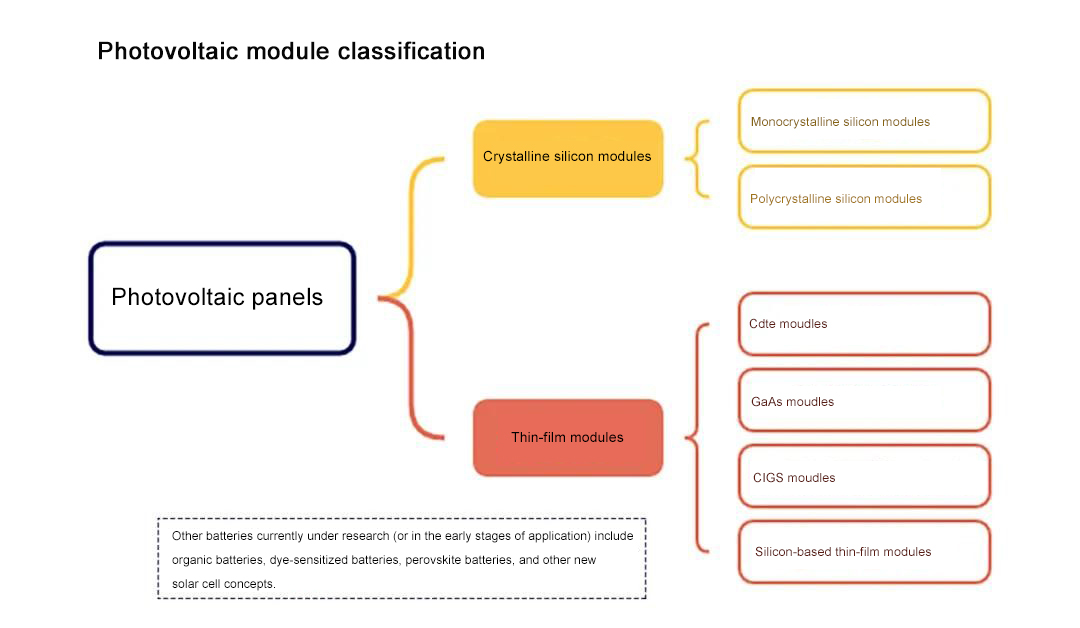

Photovoltaic modules are made from a

variety of materials, primarily crystalline silicon modules and thin-film

modules. Crystalline silicon modules are further divided into monocrystalline

silicon and polycrystalline silicon, while thin-film modules include various

types such as cadmium telluride (CdTe), copper indium gallium selenide (CIGS),

and gallium arsenide (GaAs). In my country's current photovoltaic industry,

crystalline silicon cells dominate the market due to their economic advantages.

However, in the building-integrated photovoltaic (BIPV) market, thin-film cells

have a more pronounced advantage.

This is because in BIPV projects, the angle

of illumination affects the conversion efficiency of traditional crystalline

silicon modules, reducing their ideal efficiency. In contrast, thin-film solar

cells offer significant advantages in BIPV projects due to their superior

low-light performance, low temperature coefficient, excellent durability, good

light transmittance, high aesthetics, and flexible customization.

CdTe thin-film modules are currently the

most widely commercialized thin-film module type, accounting for over 90% of

the market. CdTe thin-film modules are photovoltaic devices based on a

heterojunction of p-type CdTe and n-type CdS, formed by sequentially depositing

multiple layers of semiconductor thin films on a glass substrate. They

primarily consist of a glass substrate, a transparent conductive oxide (TCO)

layer, a CdS window layer, a CdTe absorber layer, a back contact layer, and a

back electrode.

Zoom Solar Green Energy Technology is one

of the few domestic new energy high-tech companies with independent

intellectual property rights that researches, develops, and manufactures CdTe

thin-film solar cells and modules. Zoom Solar Green Energy Technology has

invested 2.016 billion yuan in the "Western China Zero-Carbon Intelligent

Manufacturing Industrial Park" in Qinhan New City, Xixian New District,

Shaanxi Province. This park integrates industry, academia, and research,

leveraging its own production lines to achieve a 300MW production capacity for

cadmium telluride thin-film modules. The company's photovoltaic manufacturing

and core coating equipment are all in-house, and all raw materials are sourced

domestically. Zoom Solar Green Energy Technology's latest generation of cadmium

telluride thin-film modules is reportedly expected to achieve a conversion

efficiency of 17%, and this efficiency is continuously improving.

Cadmium telluride thin-film modules have a

wide range of applications in the BIPV field, including in commercial

buildings, schools, hospitals, airports, subway platforms, bus stations, and

large factory workshops. They can be used as a decorative building material,

replacing traditional glass curtain walls, exterior decorative stone, and roof

tiles, while also providing green, environmentally friendly, and clean

electricity for buildings. The following are some common examples of cadmium

telluride thin-film modules in the BIPV field:

1. Building Photovoltaic Curtain Walls

Photovoltaic curtain walls are a novel

architectural curtain wall technology that combines traditional curtain wall

technology with photovoltaic power generation technology, integrating power

generation, sound insulation, thermal insulation, safety, and decorative

features. These highly practical technologies eliminate a building's reliance

on traditional electricity sources, enabling on-site power generation and use,

saving energy and money. They do not emit carbon dioxide or produce greenhouse

gases, making them a net energy source and helping to reduce building carbon

emissions. Furthermore, they can replace some traditional building materials,

further conserving resources.

2. Photovoltaic Carports

"Photovoltaic + Carports" is a

diversified, personalized, and innovative application of the "1+N

Integrated Energy Low-Carbon Service" of cadmium telluride thin-film

modules. They not only perform all the functions of traditional carports but

also provide vehicle charging, achieving efficient energy utilization. Common

photovoltaic carports typically utilize steel structural supports, which are

simple, elegant, stylish, beautiful, and practical. They can be installed in a

wide range of locations, effectively alleviating social, environmental, and

energy pressures.

3. Photovoltaic Sunrooms

Photovoltaic sunrooms have become very

popular in recent years. First, they effectively harness solar energy to

generate electricity, providing green, renewable electricity to homes and

businesses, lowering energy costs and reducing greenhouse gas emissions.

Second, they are often more aesthetically pleasing, showcasing a sense of

artistry and technology. Third, because they utilize advanced thermal

insulation materials, they are less hot in the summer and less cold in the

winter than conventional sunrooms.

4. Photovoltaic Tiles

Photovoltaic tiles, also known as solar

tiles, are a new type of roofing material that utilizes solar energy to

generate photovoltaic power. As a technology that integrates architecture with

renewable energy, photovoltaic tiles not only generate electricity but can also

be incorporated into building components, such as roofs or walls, to enhance

the aesthetics of a building and achieve energy sustainability. The material

and installation costs of photovoltaic tiles are continuously decreasing, while

their photovoltaic conversion efficiency is continuously improving, making them

increasingly economically competitive.

5. Photovoltaic Bus Shelters

The electricity generated by photovoltaic

bus shelters can power various functions, including nighttime advertising

lightbox lighting, station information systems, real-time voice announcements,

free Wi-Fi hotspots, and USB charging ports. This reduces municipal electricity

costs, improves the waiting environment, and enhances the passenger experience.

6. Distributed Photovoltaic Power Generation

on Industrial and Commercial Rooftops

Commercial and industrial buildings

typically feature large, flat rooftops with minimal obstructions, high power

consumption, and high electricity prices, making them ideal for installing

photovoltaic power plants primarily for self-use. Distributed photovoltaic

power generation on commercial and industrial rooftops is a green and

environmentally friendly project, providing insulation, moisture resistance,

and thermal insulation for rooftops, extending their service life while

enhancing their aesthetics.

In short, cadmium telluride thin-film

modules, as a highly efficient and environmentally friendly BIPV material, help

businesses save on electricity costs, generate revenue through the sale of

surplus electricity to the grid, and participate in carbon credit trading. The

cadmium telluride thin-film module has a design life of 30 years, can achieve a

10-year product warranty and 25 years of linear power output. Through power

generation, the cost can be recovered in 6 years, helping various industries to

reduce costs and increase efficiency. It has huge application potential in the

future renewable energy field.